Engine Rebuiling-Performance Engine Rebuilding-Automotive Machine Shop

Performance Automotive ® 475 S Prairie St, Bethalto, IL 62010 (618) - 377-0027.................. Site Designed By AMS Web Designs 1-413-566-0037

Magnuflux Magnetic Particle Crack Inspection

MAGNAFLUXING CRACK DETECTION

Magnaflux Services : Engine Blocks,Crankshafts, Cylinder Heads, Connecting Rods.

Crack detection is done with the use of Magnaflux technology at Performance Automotive We have several ASTM Level II technicians trained to properly identify any inclusions before components are put back into operation. While much of this work is done for engine components, we are also set up to inspect many other non engine related components such as gears, spindles, shafts, etc.

Crack Detection/Magnaflux

Due to the age and stress of most engines the Magnaflux method is utilized to identify cracks in cylinder heads, engine blocks, connecting rods and crankshafts as well as other components of the engine that need to be checked.

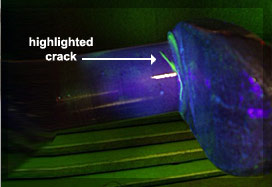

The Magnaflux process utilizes an electrical current to produce magnetism in the part being checked, a solution containing iron powder is flowed over the part. The components having been magnetized will draw the iron powder to the void area "crack" . Utilizing the ultraviolet black light clearly shows the flow "crack".

The Magnaflux process is a critical step many cracks would otherwise go unnoticed, particularly cracks in parts such as crankshafts. Cracks in crankshafts are often not visible to the naked eye.

Performace Automtive utilizes Magnaflux Stationary Machines, Portable Magnaflux Equipment , Magnaflux Liquid penetrant Processes,Florescent penetrant, Zyglo Process. Our service are offered in shop single part inspection, batch inspection.

1.Circulate specially prepared solution with Magnaflux magnetic powder.

2.Energize the component pads, probes or loop.

3.This creates a void where the crack is.

4.Next the powder gathers at the void.

5.Inspection process. Inspect the component with the Ultra violet lamp .

6. Locate the crack as seen in the pictures

Magnetic Crack Detection

The process uses an electrical current to produce magnetism in the part being checked, then a solution containing iron powder is sprayed over the part. Since the part is now magnetized the iron powder will get drawn onto the crack where using a black light the crack is plainly shown. Otherwise, without this important step many cracks would go unnoticed, particularly cracks in most parts such as crankshafts, which aren't visible to the naked eye.e process uses an electrical current to produce magnetism in the part being checked, then a solution containing iron powder is sprayed over the part. Since the part is now magnetized the iron powder will get drawn onto the crack where using a black light the crack is plainly shown. Otherwise, without this important step many cracks would go unnoticed, particularly cracks in most parts such as crankshafts, which aren't visible to the naked eye.